Understanding Types of FDM 3D Printers

Introduction

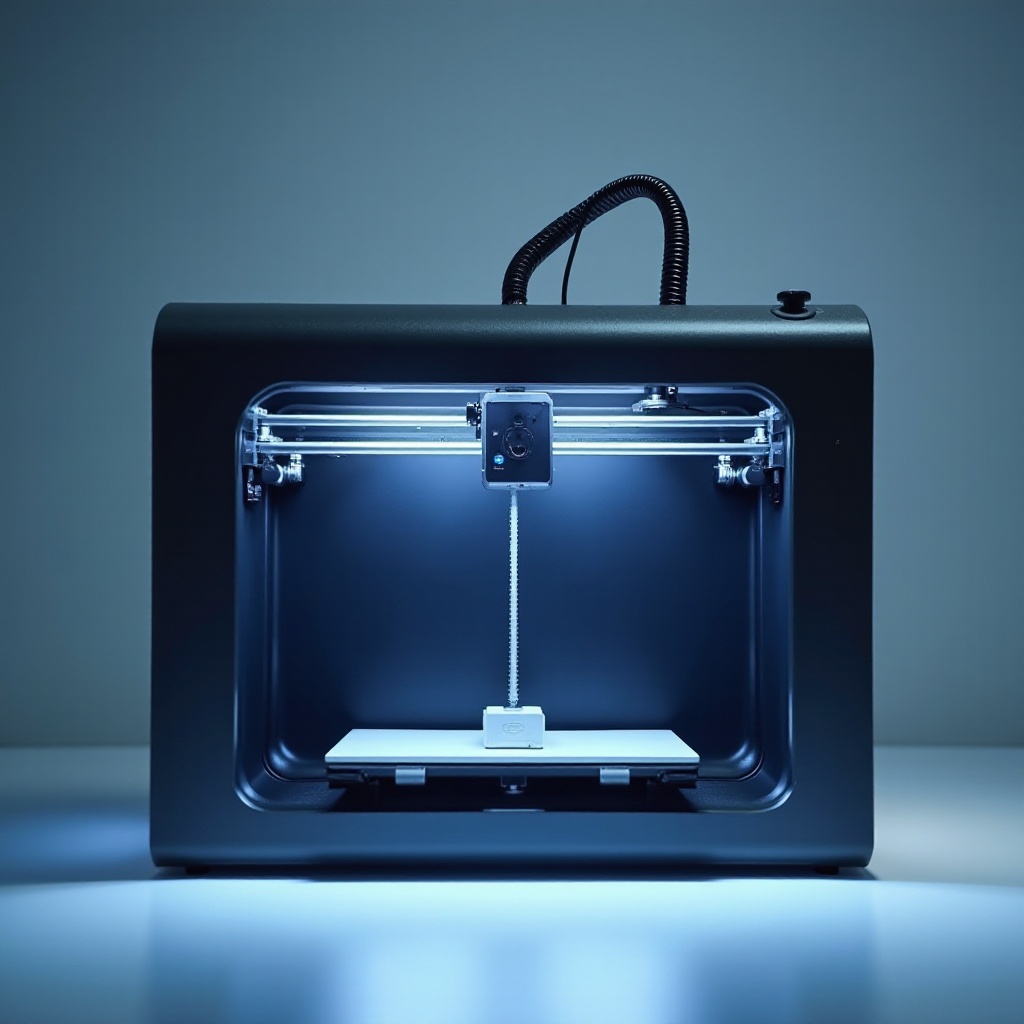

Fused Deposition Modeling (FDM) 3D printers are renowned for their versatility and accessibility. As technology evolves, choosing the right FDM 3D printer can be overwhelming without the proper knowledge. This guide delves into the various types of FDM 3D printers, their features, and factors to consider when making a purchase. Whether you’re a hobbyist or a professional, understanding these differences is crucial for making an informed decision.

What is FDM 3D Printing?

FDM 3D printing, also known as Fused Filament Fabrication (FFF), is an additive manufacturing process. It uses a continuous filament of thermoplastic material that gets heated to its melting point and extruded layer by layer to build a 3D object. This technique is widely used due to its efficiency, cost-effectiveness, and ability to create complex designs.

The process begins with designing a 3D model using Computer-Aided Design (CAD) software. The design is then converted into a format that the printer can read, typically a G-code file. The printer heats the filament and extrudes it through a nozzle, depositing the material layer by layer onto a build platform.

FDM 3D printing is favored for its simplicity and the availability of a wide range of printable materials, including PLA, ABS, PETG, and more. It’s commonly used for prototyping, custom tools, education, and even hobbyist projects. Understanding the basics of FDM 3D printing lays the foundation for selecting the right printer to meet individual needs.

Types of FDM 3D Printers

FDM 3D printers come in various categories tailored to different user needs. Generally, FDM 3D printers can be classified into three main types: entry-level, mid-range, and professional/industrial.

Entry-Level FDM Printers

Entry-level FDM printers are designed for beginners and hobbyists. They are cost-effective and easy to use, making them ideal for someone new to 3D printing. These printers offer basic features with modest build volumes and print resolutions. They are often compact and suitable for small-scale projects and educational purposes.

Examples of entry-level models include the Creality Ender 3 and the Anycubic i3 Mega. These printers are known for their affordability and reliability, providing a great starting point for learning the ropes of 3D printing.

Mid-Range FDM Printers

Mid-range FDM printers cater to more experienced users who require better performance and versatility. These printers offer larger build volumes, higher print resolutions, and improved material compatibility compared to entry-level models. They often include features like heated build plates, dual extruders, and higher temperature nozzles.

Printers such as the Prusa i3 MK3 and the FlashForge Creator Pro fall into the mid-range category. They provide a balance of quality and functionality, making them suitable for both advanced hobbyists and semi-professional applications.

Professional/Industrial FDM Printers

Professional and industrial FDM printers are designed for high-performance applications and commercial use. They feature advanced capabilities such as large build volumes, multi-material printing, and precision engineering. These printers handle demanding tasks like functional prototyping, industrial design, and on-demand manufacturing.

Notable models in this category include the Ultimaker S5 and the Markforged X7. These printers come with robust features and are built for reliability and scalability, suitable for professional environments where quality and consistency are paramount.

Key Factors to Consider When Choosing an FDM Printer

Selecting the right FDM 3D printer requires careful consideration of several key factors. These factors determine how well a printer will meet your specific needs and include build volume, print resolution, and material compatibility.

Build Volume

Build volume refers to the maximum size of an object that a printer can produce. It’s crucial to choose a printer with a build volume that accommodates the dimensions of your intended projects. Larger build volumes are beneficial for creating bigger models and reducing the need for assembly of smaller parts.

Print Resolution

Print resolution affects the quality and detail of the final print. It is measured in microns, with lower values indicating finer details. Higher print resolution is essential for applications requiring precise and intricate designs. Consider the desired level of detail when choosing a printer to ensure it meets your expectations.

Material Compatibility

The types of materials a printer can use directly impact its versatility. Basic filaments like PLA and ABS are standard, but more advanced printing may require compatibility with materials like PETG, TPU, or even composite filaments. Assess the material requirements of your projects and ensure the printer supports them.

Leading Brands and Models in 2024

As the market evolves, 2024 offers a range of impressive FDM 3D printers catering to different needs and budgets. Here are some leading models to consider:

Best All-around Models

The Prusa i3 MK4 and the Ultimaker S3 stand out for their balance of performance, reliability, and versatility. These models are well-suited for a wide range of applications and provide excellent value for the investment.

Best Budget Models

For those seeking affordable options without compromising quality, the Creality Ender 3 V2 and the Anycubic Kobra are top picks. These budget-friendly models offer excellent reliability and user-friendly features, ideal for beginners and hobbyists.

Best High-End Models

Professional users and industries might consider the Ultimaker S5 Pro Bundle and the Raise3D Pro2 Plus. These high-end models offer advanced features, large build volumes, and exceptional print quality, making them ideal for demanding applications.

Conclusion

Understanding the various types of FDM 3D printers is essential for making an informed purchase decision. Each category—entry-level, mid-range, and professional—offers unique features catering to different user needs. By considering key factors like build volume, print resolution, and material compatibility, you can find a printer that aligns with your projects and goals. Whether you’re just starting or looking to upgrade, the right FDM 3D printer can significantly enhance your creative and professional capabilities.

FAQs

What are the advantages of FDM 3D printers over other types?

FDM 3D printers are popular due to their affordability, ease of use, and versatility with a wide range of materials. They are suitable for various applications from hobbyist projects to professional prototyping.

How do I determine the right FDM printer for my needs?

Consider factors like your budget, the size and complexity of your projects, and the features you need such as build volume, print resolution, and material compatibility. Research and reviews can also be helpful in making an informed decision.

What is the expected lifespan of an FDM 3D printer?

The lifespan of an FDM 3D printer depends on usage, maintenance, and build quality. Generally, well-maintained printers can last several years, with parts like nozzles and build plates requiring periodic replacement.

By understanding the types and features of FDM 3D printers, you are well-equipped to choose a model that best suits your needs and enhances your capabilities in the exciting world of 3D printing.

Frequently Asked Questions

What are the advantages of FDM 3D printers over other types?

FDM 3D printers are popular due to their affordability, ease of use, and versatility with a wide range of materials. They are suitable for various applications from hobbyist projects to professional prototyping.

How do I determine the right FDM printer for my needs?

Consider factors like your budget, the size and complexity of your projects, and the features you need such as build volume, print resolution, and material compatibility. Research and reviews can also be helpful in making an informed decision.

What is the expected lifespan of an FDM 3D printer?

The lifespan of an FDM 3D printer depends on usage, maintenance, and build quality. Generally, well-maintained printers can last several years, with parts like nozzles and build plates requiring periodic replacement.